High-speed steel, as a high-carbon and high-alloy ledeburitic steel, features high hardness and excellent wear resistance. It maintains high hardness and wear resistance even at temperatures above 550℃ and has good red hardness. It is widely used in the manufacture of various high-speed cutting tools. Among them, high-speed steel wire is mainly used for manufacturing twist drills, taps and saw band teeth, etc.

In actual industrial production, high-speed steel wires of different sizes are mainly obtained through cold drawing. There are a large number of hard carbides inside high-speed steel wires. On the one hand, this enhances the hardness and wear resistance of the steel wires, providing excellent performance in use. However, on the other hand, the large-sized carbides do not coordinate with the matrix, causing deformation and stress concentration, resulting in a large number of defects. This seriously affects the drawing plasticity, leading to wire breakage and a decline in subsequent performance in use.

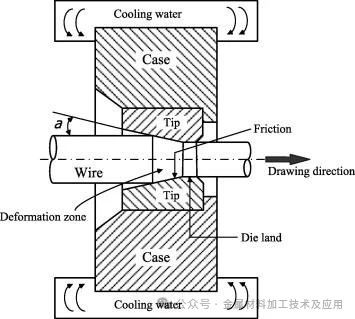

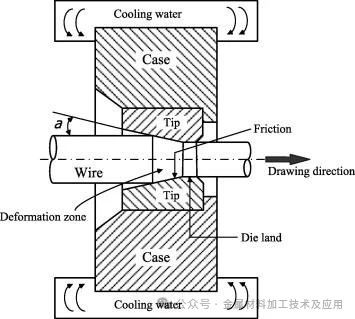

Fixed die drawing is currently the most widely used production method in the production of metal wires. Steel wires pass through wire drawing dies with different hole diameters and undergo deformation under the combined action of radial compressive stress and axial tensile stress to produce steel wires of specific specifications, as shown in the following figure.

During the drawing deformation process of high-speed steel wire, the grains inside the steel wire undergo sliding deformation under the action of external force, dislocations continuously multiply, and entangle and accumulate at the grain boundaries and carbide junctions, resulting in an increase in strength and a decrease in plasticity, making subsequent drawing deformation difficult. When the drawing speed is relatively low, the drawing force required for the steel wire increases with the increase of the drawing rate. When the drawing speed is relatively high, the drawing force decreases as the drawing rate increases. The greater the compression rate of each pass, the greater the drawing force, and the higher the improvement of the strength of the steel wire. However, its deformation is uneven, which is not conducive to the plasticity and toughness of the steel wire.